Fleet, aftermarket, parts, lubricants, featuredpost, Tenderd, Online equipment rental, Preventive maintenance, Equipment uptime, EMA Lubricants Company, ExxonMobilOnline equipment rental marketplace Tenderd and EMA Lubricants Company (ExxonMobil JV) have announced an agreement to offer maintenance services to equipment fleet owners in order for them to prevent breakdowns, increase fleet productivity and reduce project costs and delays.

Explaining the agreement’s aims and objectives, a statement from Tenderd said that the “breakdown of one single piece of machinery on-site means loss of operation, project delays and extra costs”. Since equipment and on-site work is interdependent, one single breakdown can bring the job site to a standstill. Other equipment and resources continue to absorb costs while idling by and waiting for the breakdown to be resolved. The single most important issue that causes equipment breakdown is the lack of proper maintenance.

The collaboration between EMALU and Tenderd aims to address this problem. The technology startup focuses on increasing equipment efficiency and productivity on-site with real-time data and has developed its in-house technology to identify and notify equipment owners, operators, and project foremen on predictive maintenance alerts. Collaborating with Mobil, it will offer exclusive services to its clients to ensure less equipment downtime and a higher utilisation rate.

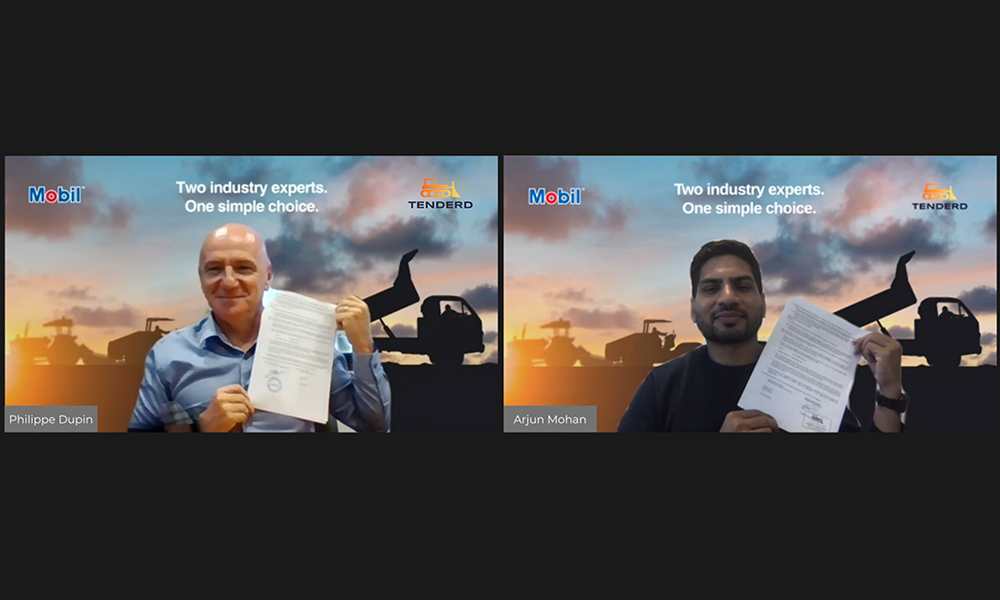

Arjun Mohan, founder of Tenderd, said: “It is very exciting to see our company collaborate with a global player in offering a large scope of different lubrication solutions that would fit each client’s needs. With this strategic association, our customers can now enjoy the benefits of using Mobil’s leading-edge industry technology and its added-value services to protect their equipment and to maximise their fleet productivity.”

Philippe Dupin, GM, EMA Lubricants Company LTD (ExxonMobil JV), said: “We are delighted with this agreement as the Mobil brand adds a new dimension to the construction segment customers through Tenderd’s leading technology platform that can ultimately standardise and change how equipment is utilised in this industry.”