Bosch says its newly launched EVO spark plugs “reliably ensure a stable ignition” throughout their service lives.

Available in the Middle East later this month, an improved isolator design and high dielectric strength increases to 45 kV means the new spark plugs can withstand events of irregular combustion – known as mega knocking – which can occur in modern highly developed engines.

Bosch EVO spark plugs are produced at the Bosch plant in Bamberg, Germany and will be compatible with the modern gasoline direct-injection engines of Volkswagen and Mercedes-Benz vehicles.

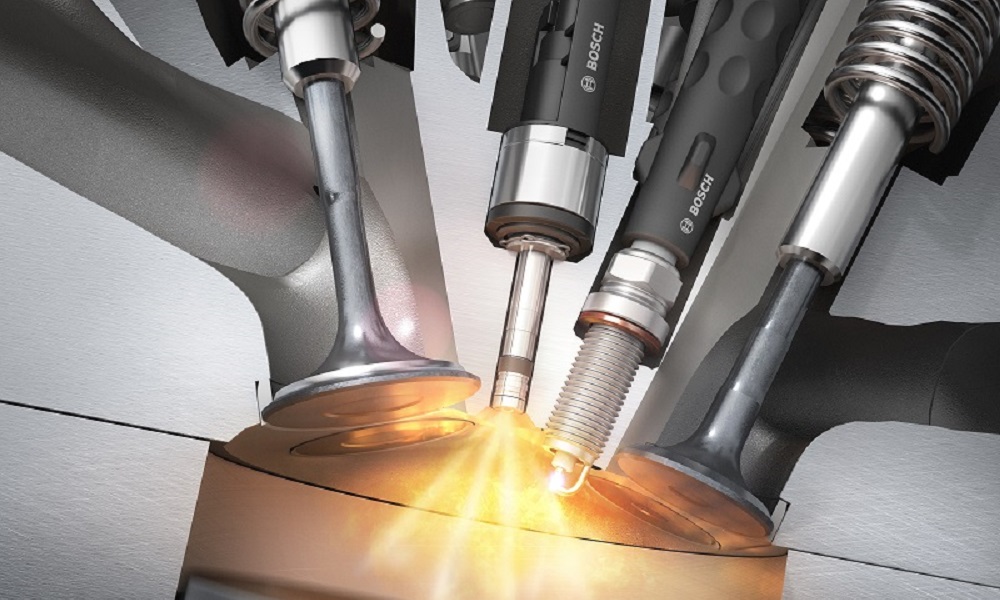

Bosch explained that the EVO spark plug was developed to ensure reliable ignition of turbocharged gasoline direct-injection engines.

“In order to make sure it copes with an increase of pressure as may occur in cases of mega knocking, it is particularly robust – thermomechanically, mechanically and electronically. The laser-welded iridium pin on the center electrode and a platinum plate on the ground electrode ensure its long service life and its high wear resistance. Featuring an improved isolator design, EVO spark plugs cope well with repeated removal and reinstallation. At their installation, the correct torque is to be observed under any circumstances. It ensures the spark plugs’ exact positioning and orientation within the combustion chamber.

“Depending on the type of engine, the demands modern engines place on spark plugs vary a lot. In close cooperation with the car manufacturers, Bosch thus develops original-equipment spark plugs geared to the specific requirements of each engine. For this purpose, Bosch engineers rely on comprehensive know-how and decades of experience in the fields of gasoline injection and ignition systems. Back in 1902, Bosch solved the issue related to the safe ignition of the air/fuel mixture by means of its first spark plug. Nowadays, Bosch offers matching spark plugs for series-production passenger cars, small engines and stationary gas engines. Lessons learned in motorsports and innovations produced for this purpose regularly influence both development and series production.

“During spark plug production, for instance, Bosch uses different electrode alloys featuring different advantages – among other things – to meet the specific requirements of each engine. Special production techniques – such as a nickel-plating process for thread and housing developed by Bosch and also used for the new EVO spark plugs – ensure improved corrosion protection and a long service life.”