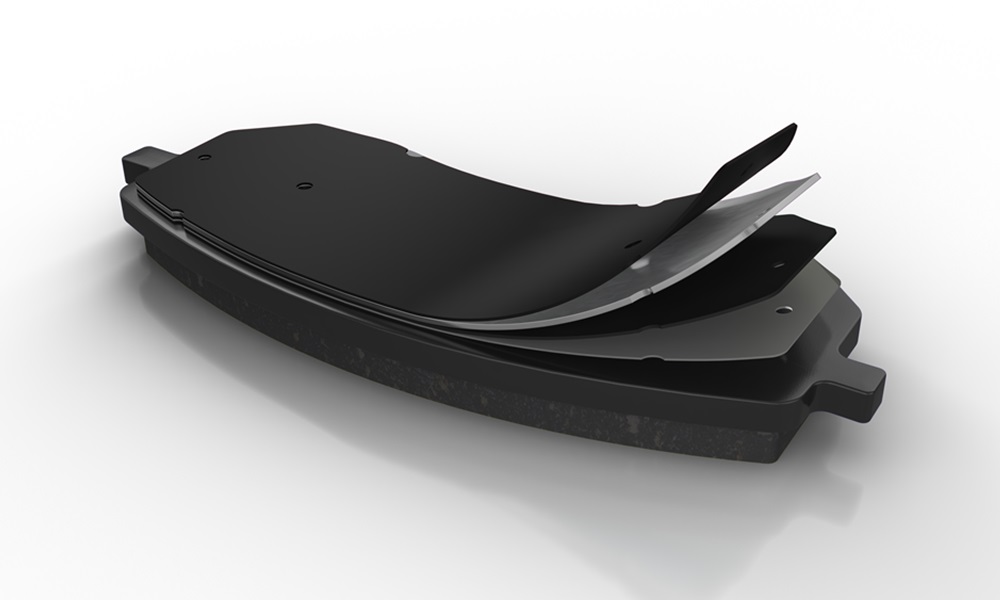

SSAB has announced a strategic agreement with Trelleborg Sealing Solutions Kalmar AB to supply fossil-free steel for use in anti-squeal plates, also known as shims, used in brake pads. Shims are crucial for eliminating brake noise, especially in electric vehicles (EVs) where unwanted sounds are more noticeable due to the quieter nature of electric drivetrains.

With sustainability being a key focus for vehicle manufacturers, particularly in the fast-growing EV market, there is increasing demand for eco-friendly components. While EVs eliminate tailpipe emissions, the materials used in manufacturing still contribute to the vehicle’s overall carbon footprint.

Trelleborg Sealing Solutions Kalmar AB, a leader in sound-damping technologies, aims to reduce the environmental impact of their brake shims through this partnership with SSAB, by using steel that boasts a significantly lower carbon footprint than traditional options.

“Our technical expertise and innovative solutions have long been used to eliminate vibration and noise in vehicles. By incorporating fossil-free steel into our components, we’re taking a significant step forward in enhancing our market leadership and contributing to a more sustainable automotive industry,” said Stefan Lundström, Business Unit President, Trelleborg Sealing Solutions Kalmar AB.

SSAB is equally enthusiastic about the partnership. “We are delighted to welcome Trelleborg Sealing Solutions as a partner in our mission to drive fossil-free innovation. Together, we will help the automotive industry meet its sustainability goals and deliver greener vehicles to consumers,” commented Olavi Huhtala, Head of SSAB Europe.

The global steel industry is a major contributor to carbon dioxide emissions. SSAB is working to change this narrative by developing two groundbreaking types of steel: SSAB Zero and SSAB Fossil-free steel.

SSAB Zero is produced using recycled steel and powered by fossil-free electricity and biogas, and has been available for commercial use since 2023. SSAB Fossil-free steel, developed using HYBRIT technology, is produced from iron ore with hydrogen made from fossil-free electricity.

This method eliminates carbon dioxide emissions, producing only water as a byproduct.

Trelleborg Sealing Solutions Kalmar AB has been at the forefront of vibration and noise-reduction technology since 1988. Their brake shims, which combine rubber and metal, are widely used by leading vehicle manufacturers worldwide to minimize noise during braking.

This collaboration between SSAB and Trelleborg is a pivotal step in reducing the carbon footprint of automotive components, aligning with global goals for sustainable mobility and cleaner production methods.