With the debut of the new BMW iX3 50 xDrive, BMW Group claims to have ushered in a new era of sustainability-led innovation under its Neue Klasse vision. Built with a full lifecycle approach to product sustainability, the iX3 integrates circular design, resource-efficient materials, and fossil-free production to significantly reduce carbon emissions — setting new benchmarks in the premium electric vehicle (EV) segment.

The BMW iX3 is the first Neue Klasse model to enter the market and represents a step forward in aligning vehicle development with BMW Group’s Net Zero ambitions for 2050 and interim targets for 2030. From raw material sourcing and manufacturing to usage and end-of-life recycling, every stage of the iX3’s lifecycle is engineered to lower emissions and preserve resources.

Early CO₂e Break-Even—Within One Year

One of the most compelling metrics to emerge from the iX3’s sustainability profile is its early carbon break-even point. When powered by electricity from the European energy mix, the iX3 outperforms a comparable internal combustion engine (ICE) BMW model after just 21,500 kilometres.

If the EV is charged exclusively with renewable electricity, the break-even point is reached after only 17,500 kilometres, allowing many customers to achieve emissions savings within their first year of ownership.

Decarbonisation Begins in the Supply Chain

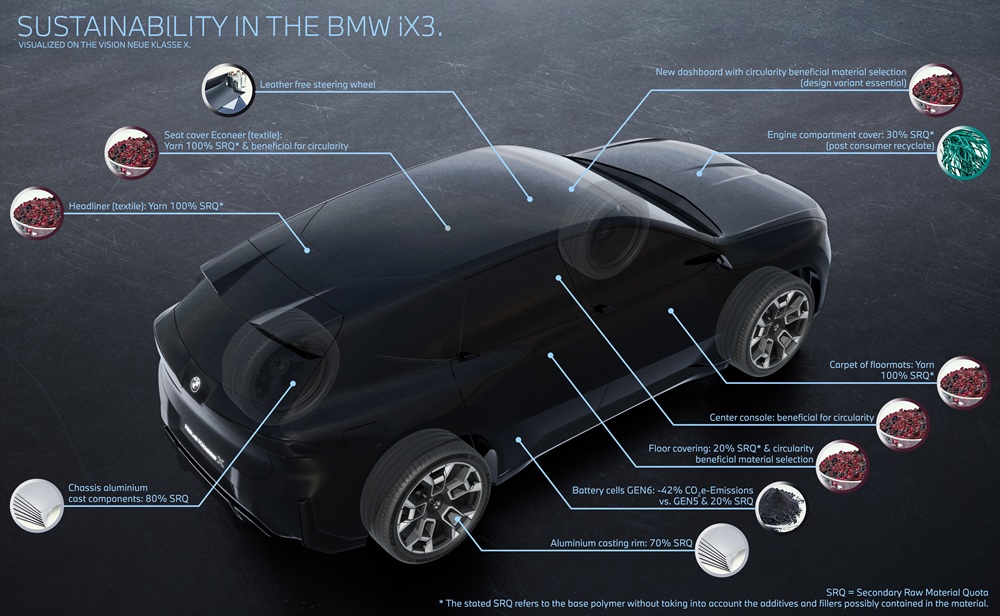

The BMW Group has adopted a rigorous strategy to tackle CO₂e emissions at source. During development of the iX3, supply chain emissions were cut by 35% through a combination of renewable energy usage and secondary raw materials. The Gen6 high-voltage battery cells, for example, are made from 50% secondary cobalt, lithium, and nickel. These same principles are applied to aluminum and plastic parts throughout the vehicle.

The engine compartment cover and storage tray beneath the front bonnet are composed of 30% recycled maritime plastic, sourced from discarded fishing gear. Meanwhile, the wheel carriers and other aluminum components use 70%–80% secondary aluminium, lowering the environmental cost of material extraction and processing.

Designed for Circularity

BMW’s “Design for Circularity” approach is a cornerstone of the Neue Klasse platform. In the iX3 50 xDrive, this philosophy manifests in the use of mono-material parts such as the Econeer seat upholstery, made entirely from recycled PET including the textile, fleece, and adhesive layers. This greatly improves recyclability. One-third of the vehicle’s overall materials are derived from secondary sources.

Interior components including the instrument panel, centre console, and floor trim are also designed with disassembly in mind, making the iX3 easier to recycle and repurpose at the end of its life.

The BMW Group applied the ‘Design for Circularity’ approach consistently in developing the BMW iX3. The approach builds on the concepts of secondary first (the prioritized use of secondary materials), strategic material selection and disassembly optimization.

One example of implementing these three concepts is the Econeer seat cover, available in the interior trim Essential, whose fabric, adhesive and fleece are all made from PET. This mono-material choice increases recyclability. Moreover, the textile yarn used consists entirely of recycled PET as well. Other components whose development followed the ‘Design for Circularity’ approach include the center console, instrument panel and interior floor trim.

Efficient, Intelligent, and Built Without Fossil Fuels

Efficiency is built into the iX3’s DNA through BMW EfficientDynamics. Aerodynamics, rolling resistance, and power consumption have all been optimised—leading to a 20% reduction in energy consumption compared to the previous generation iX3.

Manufacturing is equally advanced. The iX3 is assembled at BMW’s state-of-the-art Debrecen plant in Hungary, the brand’s first car factory to run entirely on fossil-free electricity under normal operating conditions. Only 0.1 tonnes of CO₂e are emitted during production of each iX3—two-thirds lower than production at older BMW plants. On-site solar energy, heat storage, and advanced water recycling systems further minimise environmental impact.

Verified Carbon Footprint and Lifecycle Reporting

According to current planning, up to 25% of the plant’s annual electricity needs can be covered by the photovoltaic system located on the premises. The remaining electricity is obtained from other renewable energy sources. Surplus solar energy is stored in a heat storage unit and used to heat the paint shop ovens as needed.

The carbon footprint of the BMW iX3 50 xDrive has been independently verified by TÜV Rheinland, conforming to ISO 14067 and other international standards. The total life-cycle CO₂e emissions of the iX3 are estimated at:

-

23.0 tonnes CO₂e using the European electricity mix

-

14.6 tonnes CO₂e using 100% renewable electricity

By comparison, a BMW X3 20 xDrive ICE model emits 52.8 tonnes CO₂e over the same 200,000 km lifecycle.

Sustainability That Scales

BMW’s approach to the iX3 is not an isolated case. It serves as a blueprint for the company’s entire future lineup under the Neue Klasse initiative. With scalable manufacturing processes, validated environmental performance, and market-ready circularity, the iX3 positions BMW to meet rising regulatory standards and consumer expectations for sustainable mobility—while maintaining the brand’s hallmark driving dynamics.

Looking Ahead

As EV adoption accelerates across the Middle East and beyond, the BMW iX3 offers a potential case for premium customers if they are seeking high performance with minimal environmental compromise.

The Group’s commitment to achieving at least a 40 Mt CO₂e reduction by 2030 and ultimately Net Zero by 2050 reflects its conviction that sustainability and profitability are not only compatible—but co-dependent. The company is pursuing ambitious, scientifically derived CO₂e targets for the coming years.

For instance, the BMW Group intends to reduce its CO₂e emissions by at least 40 million tons in 2030 (baseline: 2019). Ultimately, for BMW, the future of mobility is not only electric. It’s intelligent, circular, and designed with sustainability at its core.